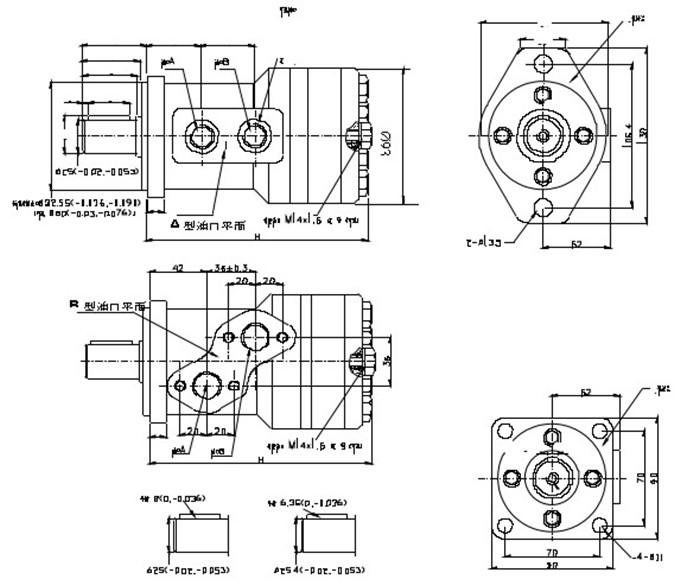

The use of axial flow matching set column rotor design:Adopt imported shaft sealing ring, with a high back pressure bear ability. variety of flange. The output shaft, and the mouth oil, and other forms of connection. Small size, compact structure. Small size, compact structure. Maximum working pressure refers to the entrance to the maximum allowable pressure, differential pressure rated pressure refers to the work.

The use of axial flow matching set column rotor design:Adopt imported shaft sealing ring, with a high back pressure bear ability. variety of flange. The output shaft, and the mouth oil, and other forms of connection. Small size, compact structure.

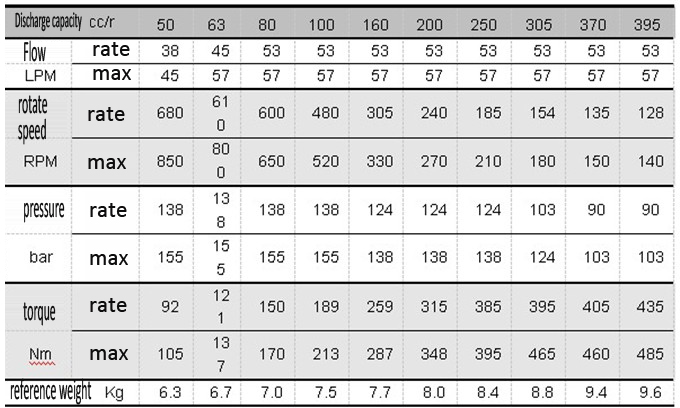

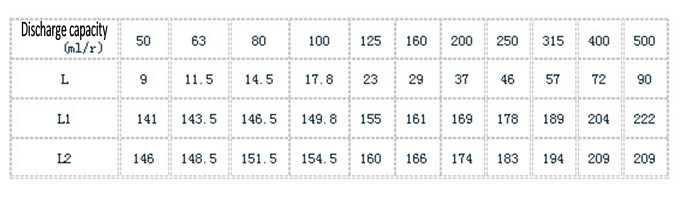

Small size, compact structure. Maximum working pressure refers to the entrance to the maximum allowable pressure, differential pressure rated pressure refers to the work. Should not be at the same time use the motor under the maximum speed and maximum pressure, the duration of the maximum working conditions allow for 6 seconds. Recommended oil, anti-wear hydraulic oil, viscosity of 37-73 CST, oil cleanliness ISO18/13, maximum working oil temperature of 80 ° C. This series of motor shaft seal component, USES the special import motors allow maximum back pressure can be up to 10 MPa, but in order to obtain a good life and comprehensive mechanical properties, it is recommended to use back pressure not more than 5 MPa, more than the suggested leaked tubing. Answer the leaking pipe, should guarantee can always full of oil in the motor, leaking pipe should keep 3.5 bar above a certain throttle back pressure, answer the leaked oil pipe besides can keep low back pressure, still can make wear away pollution status of the motor, and can produce certain cooling effect.

Add:No.8 Shanbo Road, National High-tech Industrial Development Zone,Jining

City,Shandong Province,China

Tel:+86-537-6588123

E-mail:trade@wolwa.cn

mobile 2-dimensional-code

Copyright Right © 2014 www.wolwa.cn Powered By Shandong Wolwa Industrial

Limited Company 鲁ICP备10206551号-6

Copyright Right © 2014 www.wolwa.cn Powered By Shandong Wolwa Industrial

Limited Company 鲁ICP备10206551号-6