GN5 series motor is an advanced Plane distribution cycloidal hydraulic motor.Adopt advanced design,high efficiency ,high work pressure,low start pressure,steady work,Two-way can obtain the same output torque.reliable shaft dynamic seal.There are three designs for different application:Standard motor,wheel motor,bearingless motor

GN5 series motor is an advanced Plane distribution cycloidal hydraulic motor.Adopt advanced design,high efficiency ,high work pressure,low start pressure,steady work,Two-way can obtain the same output torque.reliable shaft dynamic seal.There are three designs for different application:Standard motor,wheel motor,bearingless motor

Using advanced rotor parameter design, low starting pressure, high efficiency, stable running at low speed

Able to work under high pressure, high output torque

advanced shaft seal design,high back pressure bearing ability

Advanced and reliable linkage axle design, make the motor has a long life

Advanced with flow design, has high precision distribution flow and wear self-compensation

Motor allows the series and parallel, in series should connect leaked out pipe

The circular cone roller bearings supporting design, with large radial load capacity, makes the office of operation of the motor can be driven directly

Wheel motor:flange in the middle of the motor,more conducive to the load ability of motor,and also it can be settled in the middle of wheel,with compact structure.

Bearingless motor :no output axle and bearing .Spline coupling output torque directly.Used in some special case,dimension more smaller,more compact.There must have the suitable internal spline when using this kind of motor.

Compact structure, small volume, drives the working parts directly, reducing the mechanical coupling system need, provides extensive adaptability for the system design

the special linkage shaft spline design makes the motor has high service life and reliability

High volumetric efficiency makes the motor has the stable speed, steady load speed characteristics, can easily realize speed regulation

Advanced manufacturing technique to ensure the motor under different conditions of use has stable performance

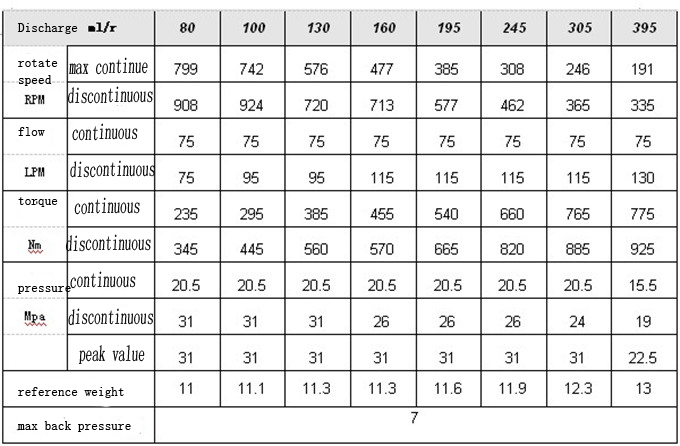

Don't use motor with max torque and max rotate speed.

Torque values listed in the table is suitable for the 32 mm in diameter and 1.25 "output shaft, 1" allow maximum continuous output shaft torque and discontinuities

Exceeds allowed back pressure, can leak tube, and ensure the motor chamber can always filled with hydraulic oil

Peak pressure of inlet pressure, the largest continuous pressure. Intermittent pressure all work for the oil return differential pressure, but not less than the peak pressure inlet pressure

The motor stopped working duration less than 6 seconds; Peak work duration of not more than 0.6 seconds

The system maximum working temperature: 80 ° C

Recommended oil, anti-wear hydraulic oil, the work under the condition of not less than 13 cSt viscosity. Filtration precision: ISO 18/13

Before the motor full load of work, should be under 30% of the rated pressure running about 1 hour, to ensure that the motor before full filled with hydraulic oil

Motor continuous working pressure and working pressure under different flow rate under the same specification, the pressure will be different, as shown in the different working point of performance parame

standard veer

Face output axle,A is entrance B is exit.motor rotated in clockwise.

Add:No.8 Shanbo Road, National High-tech Industrial Development Zone,Jining

City,Shandong Province,China

Tel:+86-537-6588123

E-mail:trade@wolwa.cn

mobile 2-dimensional-code

Copyright Right © 2014 www.wolwa.cn Powered By Shandong Wolwa Industrial

Limited Company 鲁ICP备10206551号-6

Copyright Right © 2014 www.wolwa.cn Powered By Shandong Wolwa Industrial

Limited Company 鲁ICP备10206551号-6